Product Description

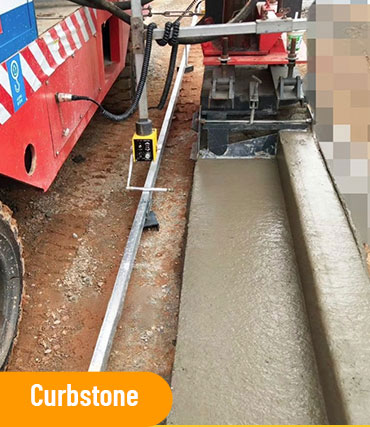

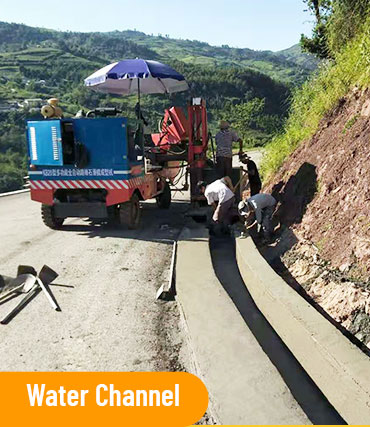

Concrete curb slipform machine is a heavy-duty road construction equipment specially used for continuous pouring and one-time forming of concrete curbs at the construction site. It has completely changed the traditional prefabrication installation method and greatly improved the efficiency and integrity of the curb.

Working Principle

A spiral blade is installed in front of the forming mold. The blade rotates continuously, pushing the cement concrete into the forming mold to extrude the curbstone. A vibrating rod is installed in front of the forming mold. The high-frequency vibration of the vibrating rod makes the cement concrete reach a certain density. The machine moves forward relying on its own power.

Product Parameters

The following are the parameters of the hot-selling curb slipform machine. If you don’t find the parameters that suit your project, you can contact me. We also have machines for small and large projects.

| Model | KB-20 | KB-30 |

| Type | Wheel type | Crawler type |

| Steering system | Automatic steering system | Automatic steering system |

| Engine(kw) |

65kw four-cylinder turbo diesel engine |

65 |

| Rated speed(rpm) | 1500 | 1500 |

| Curb size(mm) |

Height≤600 width≤2000 |

Height≤1100 width≤2000 |

| Minimum turning radius(mm) | 6800 | 6800 |

| Paving speed(m/min) | 1—7 adjustable | 1—10 |

| Weight(kg) | 6000 | 7000 |

Advantages

Four-track chassis

The whole machine has super strong grip and excellent flatness of the sliding mold!

Dual auto steering system

It can reduce the position deviation of the sliding mold at the bend by more than 95%, thus ensuring the road width!

Anti-slip self-locking function

During the construction process, no matter uphill or downhill, there is no need to brake! The machine automatically maintains the set travel speed and “never slips”!

Tracks and tires interchangeable

Convenient for short-distance transitions and adaptable to different working conditions!

Applications

Multiple usage ranges can cope with various scenarios.We have a variety of molds, one size corresponds to one mold, and mold customization is supported.

Related Products

Shipping And Packaging